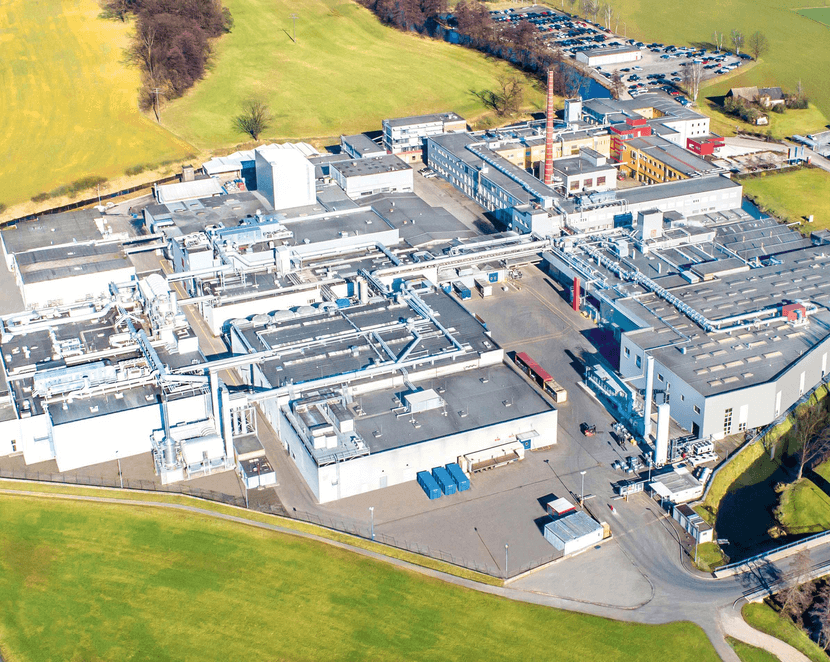

Constantia Pirk Germany

Constantia Pirk is the second largest plant within the Constantia Flexibles Group and produces packaging materials for the consumer and pharma industry.

In Short

Constantia Pirk is located in Pirk in the south of Germany near Munich. We serve the consumer and pharma industry. Our services cover the whole product life cycle starting with the development of the design and specification through to the use of the products on the packaging machines.

In the field of logistics and production we pursue an uncompromising approach based on measures suited to our clients. Our pharma production facility was built to meet clean-room requirements, which is clearly oriented towards the needs of the pharmaceutical industry. The integrated pre-press with in-house printing-cylinder manufacturing also gives us the opportunity to operate independently and flexibly in this field.

Quality Certificates

Strict quality control is realized by means of state-of-the-art equipment and procedures. Constantia Pirk ensures the highest standards in quality, food safety and regulatory affairs related topics. We see our responsibility towards our employees as an essential component and guarantee this with health protection and occupational safety. Furthermore, we dedicate ourselves to saving energy, conserving resources and environmental protection. Constantia Pirk fully complies with sustainability requirements as well as with FDA/IMS requirements for supplying the US market. In addition, we optimally serve the needs of our customers with primary packaging materials for medicinal products. Social and ethical responsibility are high values for us and an important part of our company policy. Therefore, Constantia Pirk is certified against: ISO 9001, BRC, ISO 50001, FSC®CoC (FSC® C119263), FDA/IMS, ISO 15378 and SMETA “Letter of Conformity”.

Key Data

History

1920

Establishment of the company as aluminium rolling mill

1991/1992

Introduction of ISO 9001 / Opening of new production line for flexible packaging

2007

Acquired by Constantia Flexibles

2015

French investor Wendel has shares of 62%, Arepo Foundation (G. Turnauer) 27% and Maxburg C. Partners 11%

2024

One Rock Capital Partners, LLC becomes the sole owner of Constantia Flexibles.

Technologies

Blow film extrusion

Metallization (Al and AlOx)

Basic converting

Lacquering, Laminating (solvent based, solvent free, wet lamination)

Printing

Rotogravure printing and Flexo printing

Finishing

Slitting, Embossing, Die Cutting

Specialities

- In-house lacquer development and production (almost exclusively for own use)

- Modern R&D department, State of the art laboratory

- Competence Centre Film, film recipe development (laboratory extrusion line)

- Prepress department (electronic image processing, cylinder manufacturing for rotogravure and flexo cylinder, using standard engraving, laser engraving and etching)

- On-site product management and application engineering for customized products

- On-site group SSC SAP

Career

At Constantia Pirk we have been developing and producing flexible packaging for the food and pharmaceutical sector for 100 years. Founded as a family business, you can still feel the family flair today. This is confirmed by our almost 800 employees who describe us as an attractive, safe and high-loyalty employer in the region. Today we have nearly about 75 apprentices (approx. 25 every year) who are taking their first steps in their career path with us. We educate in eight different certificated high-quality apprenticeships to ensure professional knowledge at our plant. With our social responsibility for the region our goal and vision is to further develop and strengthen our plant. Be part of our family and experience every day what people, passion, packaging means to you.