Constantia Tobepal Burgos Spain

In Short

Constantia Tobepal consists of two production plants in the north of Spain.

The site in Burgos has 270 employees and is focused on HPC, Food and Label products and the site in Logroño has 225 employees and is mainly focused on Pharma and Food.

Quality Certificates

Strict quality control is realized by means of state-of-the-art equipment and procedures. Constantia Tobepal Burgos ensures the highest standards in quality, food safety, regulatory affairs and GMP related topics. We see our responsibility towards our employees as an essential component and guarantee this with health protection and occupational safety. Furthermore, we dedicate ourselves to saving energy, conserving resources and environmental protection. Constantia Tobepal Burgos fully complies with sustainability requirements. In addition, we optimally serve the needs of our customers with primary packaging materials for medicinal products. Social and ethical responsibility are high values for us and an important part of our company policy. Therefore, Constantia Tobepal Burgos is certified against: ISO 9001, BRC, ISO 14001, Kosher, Halal, PEFC, FSC®(FSC - C135867), ISO 15378 and SMETA “Letter of Conformity”.

Key Data

Technologies

Basic Converting

Adhesive lamination, Extrusion lamination, Co-extrusion coating

Printing

Rotogravure printing

Metallization

Bi-lacquering, Metallization

Finishing

Reel slitting / Laser perforation, Embossing, Pre-made bags making

Specialities

- In-house artwork.

- Modern R&D Department for Pharma Laminates (Product Excellence Center) to develop the next generation of laminates for the pharmaceutical market.

- Custom-made product and service solutions for our customers at the highest level.

- Metallization for the beer market mainly and also with new development for sustainable solution in the food market.

- Pre-made bags making for PET food market mainly.

Career

Constantia Tobepal offers work stability to its employees along with a process of continuous training. And provides its employees with opportunities to grow as a professional and promotes professional integration, motivating its employees and providing access to all opportunities for professional development.

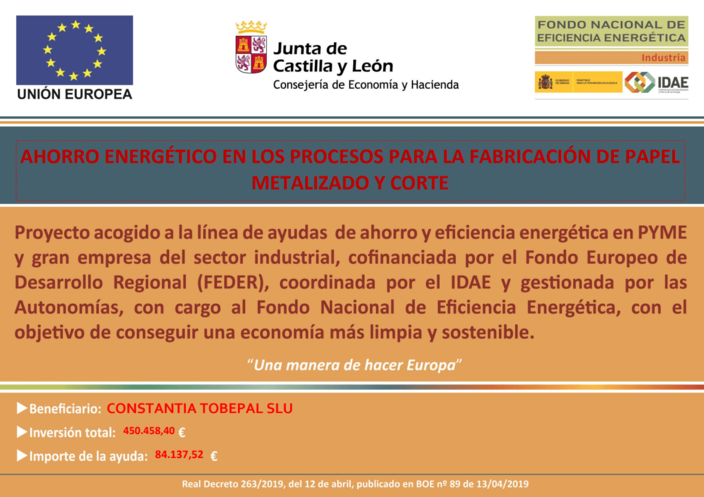

Proyecto de ahorro y eficiencia energética – Unión Europea

Constantia reconoce la innovación como un motor clave para el crecimiento rentable y se esfuerza por convertirse en el líder en innovación. Consta de dos plantas de producción en el norte de España enfocada una de ellas en Burgos en los productos HPC, alimentación e Industrial, la planta de Logroño, en cambio, se encuentra enfocada a Farmacia y Alimentación.

Las tecnologías empleadas son la conversión clásica (impresión, laminación por adhesivos, laminación por extrusión, recubrimiento por coextrusión y metalización) y el acabado (corte de bobinas, perforación láser, gofrado, fabricación de bolsas prefabricadas), todo ello con un enfoque centrado en la sostenibilidad.

En el proceso de metalización de Constantia han intervenido la máquina bi-lacadora y la bobinadora, de manera que se logre reducir la energía necesaria para efectuar las tareas de corte.

El proyecto que se presenta de mejora de tecnología de equipos asociada al proceso industrial de metalización (lacado y corte) y resto de proceso de rebobinado ha consistido principalmente en la incorporación de un sistema de corte en línea en la máquina bi-lacadora y la sustitución de una bobinadora de corte, por otra más eficiente energéticamente, con el fin de reducir el consumo de energía final.

Con la instalación de la nueva bobinadora se pasa de un consumo eléctrico de 351.848,67 kWh a 152.880,00 kWh y con el nuevo módulo de corte en línea se va a lograr pasar de un consumo eléctrico de 770.280,00 kWh a tan sólo 23.520,00 kWh

El proyecto se ha llevado a cabo para conseguir la reducción en la energía empleada en el proceso, obteniendo un ahorro de 84,27% en la energía eléctrica empleada, gracias a la mejora del proceso de metalización y corte reduciendo de manera drástica la energía final empleada.

Gracias a la financiación de la Unión Europea y el Fondo Nacional de Eficiencia Energética (IDAE) se han conseguido los resultados para lograr el ahorro energético en los procesos de metalización y corte.

Proyecto de Autoconsumo con Energía Solar Fotovoltaica – Unión Europea

En Constantia Tobepal, S.L.U. seguimos avanzando en nuestro compromiso con la sostenibilidad y la eficiencia energética. Hemos completado la instalación de un sistema de generación eléctrica para autoconsumo mediante energía solar fotovoltaica, una iniciativa que contribuye a la reducción de emisiones y a la optimización de nuestros costes energéticos.

Este proyecto se enmarca en el Programa de incentivos ligados al autoconsumo y almacenamiento con fuentes de energía renovable, dentro del Plan de Recuperación, Transformación y Resiliencia, financiado por la Unión Europea – NextGenerationEU.

Datos Clave del Proyecto

Potencia instalada: 700 kW

Número de paneles: 1.550 módulos fotovoltaicos

Superficie ocupada: 3.456 m²

Inversión total: 557.382 €

Importe de la ayuda recibida: 83.607,30 €

Normativa aplicable: Real Decreto 477/2021

Vida útil estimada: 25 años

Impacto Ambiental y Energético

Reducción del consumo eléctrico: -10,57%

Reducción de emisiones de CO₂: 230 toneladas/año

Generación eléctrica anual estimada: 921.120 kWh

Beneficios Estratégicos

Contribución a la transición energética y reducción de dependencia de combustibles fósiles.

Mitigación del impacto de la subida del precio de la electricidad y de los costes asociados a derechos de emisión.

Mejora de la competitividad y sostenibilidad de nuestros procesos productivos.

Este proyecto refuerza nuestra posición como referente en innovación y sostenibilidad dentro del sector del packaging flexible. La instalación de energía solar fotovoltaica no solo supone un avance tecnológico, sino también un compromiso firme con la reducción del impacto ambiental y la mejora continua de nuestros procesos productivos.

Gracias a la colaboración institucional y a la financiación europea, hemos podido implementar una solución que contribuye a los objetivos globales de descarbonización y transición energética. Esta iniciativa nos permite reducir significativamente las emisiones de CO₂, optimizar el consumo eléctrico y garantizar un modelo de producción más eficiente y responsable.

Con este paso, Constantia Tobepal se alinea con las mejores prácticas del sector y con las exigencias de nuestros clientes, que cada vez valoran más la sostenibilidad como parte esencial de la cadena de suministro. Seguiremos trabajando en proyectos que impulsen la innovación y la protección del medio ambiente, consolidando nuestra posición como empresa líder en soluciones sostenibles para el packaging flexible.

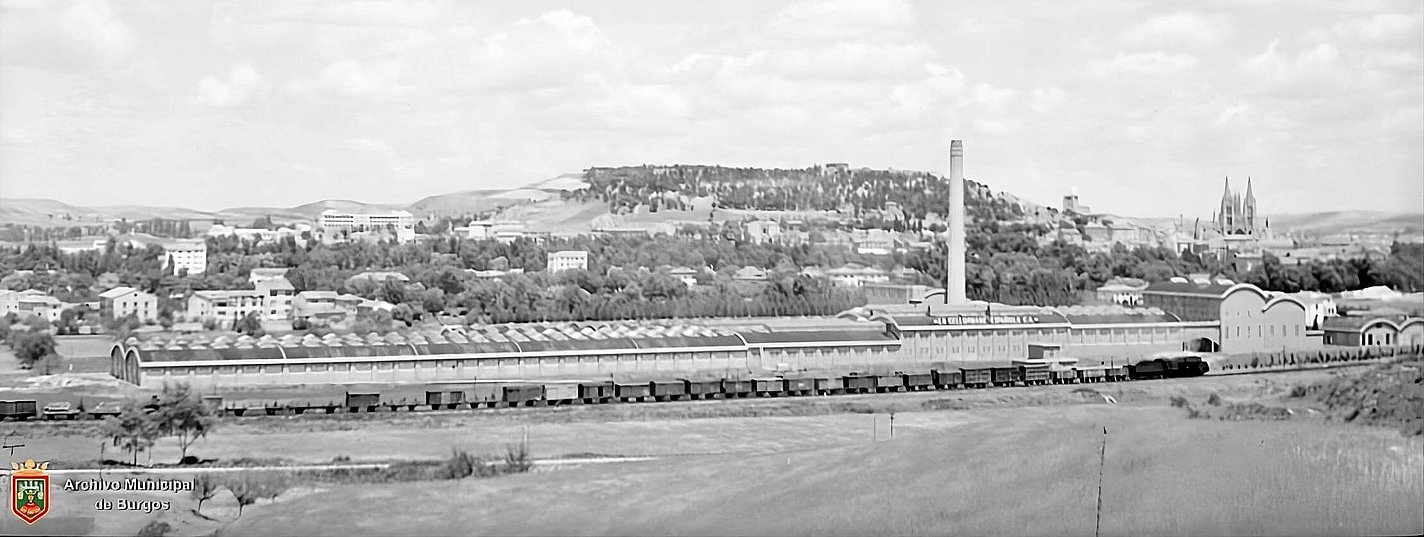

A journey of 75 years: Constantia Flexibles Burgos in the packaging industry

Brief history: From La Cellophane Española to Constantia Flexibles

Constantia Flexibles Burgos was originally established as La Cellophane Española on July 29, 1949, in the Las Huelgas neighborhood of Burgos. The factory was a pioneer in producing "cellophane" paper and quickly diversified into new processes such as printing, lamination, metallization, and the production of polyethylene, PVC, and metallized paper. Despite the decline of cellophane production due to the rise of polypropylene, the company adapted and continued its flexible packaging operations.

2001, the company moved its machinery and employees to the Villalonquéjar industrial area. Constantia Flexibles acquired the site in 2010, further enhancing its capabilities. The Logroño plant, acquired in 2002, specializes in extrusion lamination and houses an R&D center for pharmaceutical laminates.

Furthermore, the Burgos plant specializes in producing metallized paper primarily used for manufacturing labels on beer bottles destined for European and American markets.

In 2023, the company's two Spanish plants collectively produced 216 million square meters of this material, enough to cover 20,131 soccer fields. Over the past five years, Constantia Flexibles has invested 27 million EUR in Spain, with 15 million EUR allocated specifically to the Burgos plant.

Today, Constantia Flexibles is one of the world's leading manufacturers of flexible packaging for the pharmaceutical and food sectors. It employs almost 10,000 people globally, 500 of whom work in Spain and about 250 at the Burgos plant.

Outlook: Innovation and sustainability

Constantia Flexibles is committed to environmental protection and sustainability. The plant has reduced CO2 emissions by 62% over the last five years and installed 7,000 sqm of solar panels, covering more than 15% of its electricity needs. The company is pioneering the manufacture of more sustainable packaging with recyclable mono materials such as polypropylene (with products like PERPETUA and EcoVer), polyethylene (EcoLam), paper (EcoPaper), and aluminum (EcoAlu), in line with new European regulations.