FACHPACK 2024: Constantia Flexibles unveils innovative packaging solutions

This September, in addition to its latest products, the company will introduce a unique service in the market for dairy customers at FACHPACK in Nuremberg at booth 4-302 in Hall 4.

Vienna, August 5, 2024

Constantia Flexibles, a global leader in flexible packaging solutions, will present its latest innovations at FACHPACK 2024 in Nuremberg, Germany, from 24 to 26 September 2024, focusing on more sustainable innovations. The company already offers a recyclable alternative for more than 90% of its portfolio. Constantia Flexibles takes a 360-degree materials approach, providing aluminum, film, and paper solutions for diverse consumer markets. By collaborating with its customers, the packaging manufacturer ensures the optimal solution for each product while expanding its sustainable offerings, e.g. with its digital printing solutions.

Marc Rademacher, Executive Vice President Consumer Commercial of Constantia Flexibles, emphasized the company’s focus on innovation, stating, "Digital printing is our latest technical advancement, a unique printing technology for aluminum die-cut lids. We also strive to offer a wide range of products designed for recycling across all segments, including our product innovation, EcoTwistPaper and compostable EcoPressoLid."

Digital printing is our latest technical advancement, a unique printing technology for aluminum die-cut lids.

Digital printing: Constantia Flexibles' industry-first aluminum prints, created specifically for die-cut dairy lids

Constantia Flexibles is currently the only flexible packaging company able to digitally print full-surface and water-based on aluminum without compromising sealing conditions. The technology supports printing on aluminum and PET and will be extended to all substrates in due time. With a competitive speed, products can be delivered in unprecedented time from design approval to shipping. This service offers flexibility by eliminating the need for printing clichés, plates, or cylinders required in other printing techniques. Moreover, less artwork preparation at Repro House reduces costs and Constantia Flexibles’ digital printing offer covers 93% of all Pantone colors, ensuring consistent printing quality every time. The digital printing service supports short-runs and reduces working capital, allowing for multiple customizations within a batch while minimizing material waste. Additionally, the water-based inks used meet food safety and sustainability standards.

Enabling more sustainable solutions

Constantia Flexibles will demonstrate its commitment to sustainability with advanced printing techniques and an array of innovative products from its Ecolutions range. Among these, is Constantia Flexibles’ Low Carbon Aluminum (Lowcarbalu) which significantly reduces the environmental impact of aluminum production. It cuts carbon emissions compared to traditional aluminum while maintaining high performance and durability. and aligning with global sustainability goals.

This year’s product highlights at FACHPACK include applications of Lowcarbalu, specifically EcoPeelCover and EcoAluTainer. Constantia Flexibles will also showcase various packaging solutions in different segments: EcoPeelCover and PPCover for lidding solutions, especially in the dairy segment; EcoPressoLid as coffee capsule lidding; EcoAluTainer for processed meat; and EcoTwistPaper, EcoLam, and EcoVer for confectionery and other segments. All of these products are designed for recycling and ensure excellent goods preservation.

Dairy: High-performance packaging for optimal freshness and safety

EcoPeelCover: Award-winning lid designed for recycling

Featuring high barrier properties and an easy peel coating for smooth opening, EcoPeelCover excels on various packaging lines and offers consistent opening behavior. With reliable sealing and high corrosion resistance, it operates at temperatures from 180°C to 230°C and is compatible with PP and PE cups. Providing an increased shelf life, it is ideal for dairy products. EcoPeelCover supports sustainability by reducing aluminum thickness by 25% and the coating layer by 50%. It comes with solvent-free UV-Flexo printing, and the carbon footprint is reduced through less material use and lighter transport weight. Moreover, EcoPeelCover is available in Low Carbon Aluminum with ASI-certified quality on demand. Because of its innovative character EcoPeelCover won the German Packaging Award 2024 in the sustainability category for material reduction.

PPCover: Mono-polypropylene lid with effective sealing and heat resistance

PPCover is a polypropylene-based die-cut lid, offering a sustainable and efficient packaging solution. Key benefits include great opacity, excellent puncture and tear resistance, and metal-free composition, allowing for proper sorting in the metal detection. PPCover also boasts improved heat resistance and seals effectively with standard flat sealing tools, specifically against PP cups. It is ideal for applications such as yogurts, other dairy products, non-carbonated beverages, and non-retort-ready meals.

EcoLam and EcoVer: Established product families designed for recycling and versatility

Designed for the PE recycling stream: EcoLam product family

The EcoLam product family features polyethylene (PE) laminates designed to replace non-recyclable options like PET/PE and other multi-material laminates. In addition to the standard EcoLam, there are different barrier levels available, namely EcoLamPlus and EcoLamHighPlus. EcoLamHighPlus offers barrier values close to PET/Alu/PE laminates. These industry-leading mono-polyethylene laminates are lighter, offer excellent thermal resistance, and use less barrier polymer. All grades are RecyClass certified and compatible with standard sorting and recycling technologies used in Europe.

Based on mono-polypropylene: The EcoVer family

EcoVer is Constantia Flexibles’ mono-polypropylene (PP) offer, which is available in different barrier grades: EcoVer, EcoVerPlus, and EcoVerHighPlus. Applicable on VFFS and HFFS lines, its high transparency, low initial sealing temperatures, heat resistance, and stiffness facilitate the use for a wide range of products. The laminates are designed for recycling according to contemporary ‘Design for Recycling’ guidelines.

Processed meat & beverages: Ensuring quality preservation and optimal freshness

EcoPressoLid: Home compostable capsule lidding

The newly introduced home compostable coffee capsule is a result of a collaboration between Greiner Packaging and Constantia Flexibles. This lid made by Constantia Flexibles is home compostable, biobased, and ideal for sealing compostable coffee capsules. It features a high oxygen barrier that maintains the coffee’s freshness and performs excellently during the brewing process.

EcoAluTainer: Design-for-recycling aluminum packaging for preserved foods

EcoAluTainer, also available with Lowcarbalu, is a lightweight recyclable solution, ideal for preserving both human and pet food products. Featuring high aluminum content, it supports the principles of a circular economy. This lightweight and stackable container also offers ASI-certified aluminum and avoids critical substances like BPA-containing epoxy resins. EcoAluTainer is retortable, ensuring it meets strict performance and quality standards while remaining a safe and eco-friendly choice for human and pet food packaging. Its versatility makes it suitable for various applications, including retort sausage packaging, dry pet food, drink pouches, and more, providing sustainable and effective solutions for both human and pet food sectors.

Confectionery: Wraps and laminates for optimal shelf life and recycling

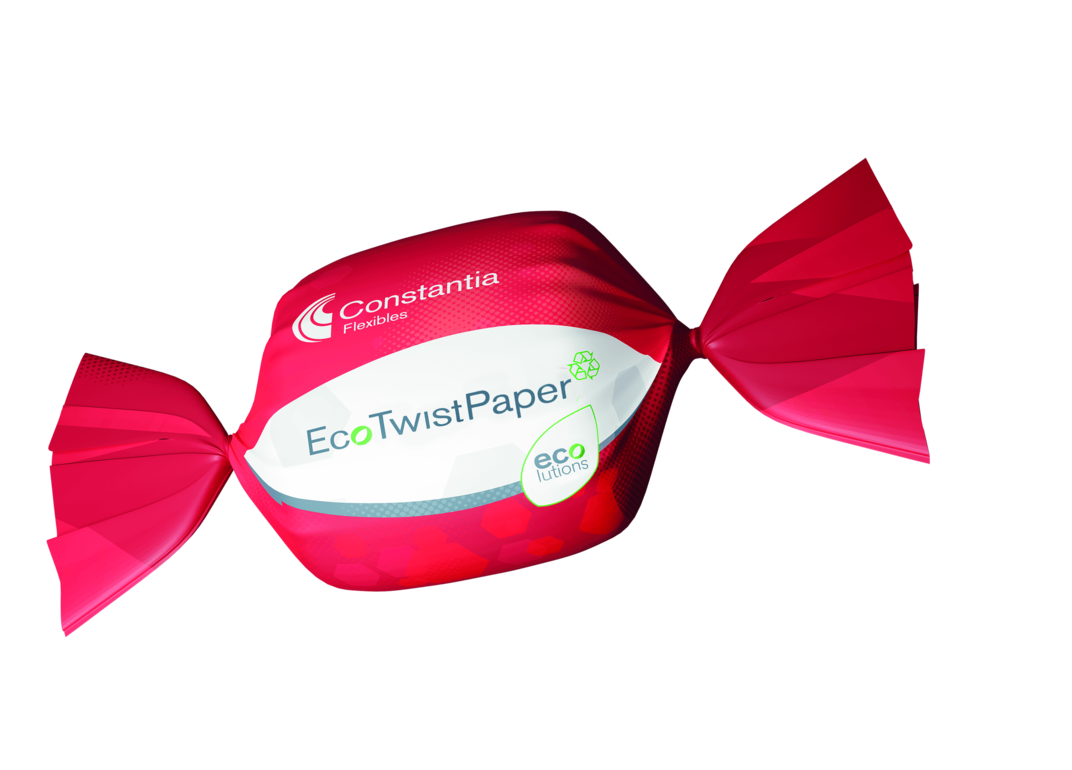

EcoTwistPaper: Recyclable paper wrap for confectionery

One of the latest Ecolutions family members, EcoTwistPaper, is an innovative, wax-free twist-wrap made from paper, prioritizing recyclability for the confectionery industry. The product has undergone repulpability testing with the Confederation of European Paper Industries (CEPI) and has scored 90 out of 100 points for its printed material. EcoTwistPaper is exempt from the Single-Use Plastics Directive due to its plastic-free composition. It is ideal for confectionery wrapping due to its compatibility with existing machinery and the softness achieved through advanced treatments.

Constantia Flexibles is the world’s third-largest producer of flexible packaging. Based on the guiding principle of ‘People, Passion, Packaging’, over 9,580* employees manufacture tailor-made packaging solutions at 36* sites in 16* countries. Many international companies and local market leaders from the consumer and pharma industries choose the sustainable and innovative products of Constantia Flexibles. Sustainability is a top priority in product development at Constantia Flexibles: the company was rated Level A- by Climate Change Leadership (CDP) and Gold by EcoVadis in 2023. www.cflex.com